Plastic Processing Machinery Market Size, Share & Trends Analysis Report 2026- 2035

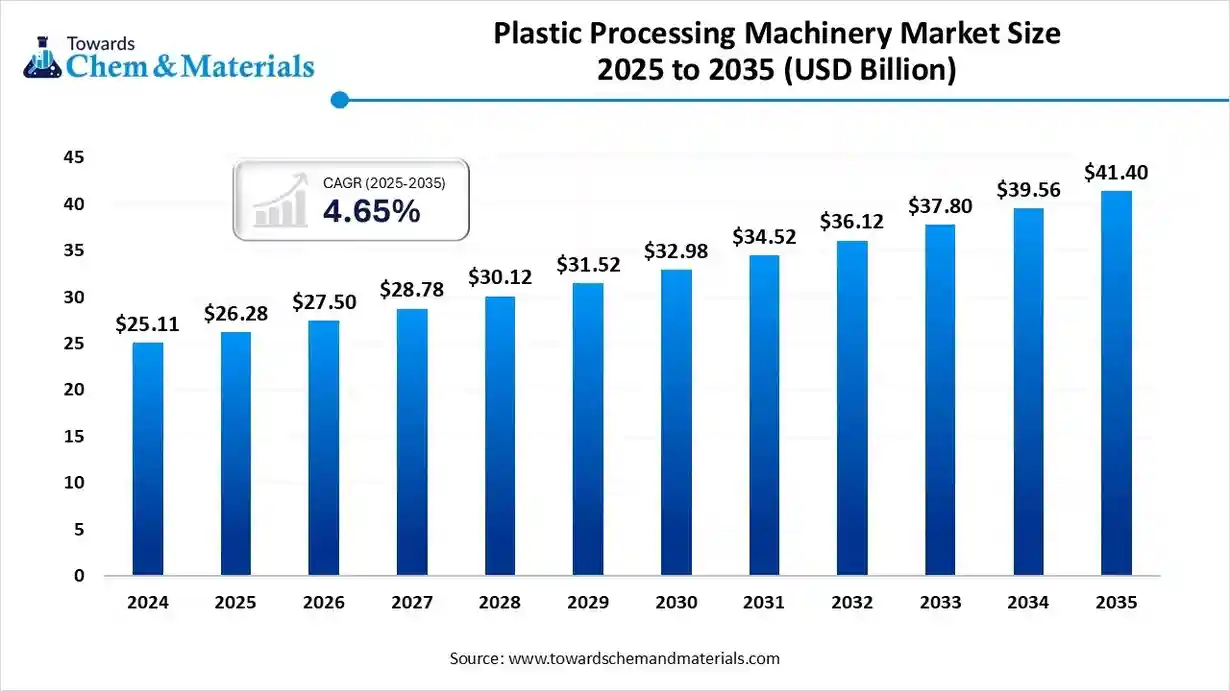

According to Towards Chemical and Materials Consulting, the global Plastic Processing Machinery market size is calculated at USD 26.28 billion in 2025 and is expected to be worth around USD 41.40 billion by 2035, growing at a compound annual growth rate (CAGR) of 4.65% over the forecast period 2026 to 2035.

Ottawa, Nov. 26, 2025 (GLOBE NEWSWIRE) -- The global plastic processing machinery market size was valued at USD 26.28 billion in 2025, the market is projected to grow from USD 27.50 billion in 2026 to USD 41.40 billion by 2035 at a CAGR of 4.65% during the forecast period. North America dominated the Plastic Processing Machinery market with a market share of 36.4% in 2025. Rising demand for lightweight, high-performance plastic components in the automotive and packaging industries is a key growth factor driving the plastic processing machinery market. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/5992

What is Plastic Processing Machinery?

The plastic processing machinery market involves machines that convert raw plastics into finished products via moulding, extrusion, and recycling processes. Its growth is fuelled by rising demand from sectors like packaging and automotive, along with a shift toward sustainable plastics. Innovation in automation, energy-efficient systems, and “smart” machinery is accelerating market expansion. Emerging regions are playing a major role in driving growth, supported by favourable manufacturing policies and increasing industries.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

Plastic Processing Machinery Market Report Highlights

- By region, Asia Pacific dominated the market with a 36.4% share in 2024 and is expected to grow at the fastest CAGR of 6.0% over the forecast period.

- By region, North America is expected to grow at a notable CAGR over the forecast period.

- By type, the injection molding machines segment dominated the market with a 48.3% share in 2024.

- By type, the blow molding machines segment is expected to grow at the fastest CAGR of 5.0% over the forecast period.

- By operation mode, the hydraulic segment held 54.4% market share in 2024.

- By operation mode, the electric segment is expected to grow at the fastest CAGR of 5.1% over the forecast period.

- By material, the polypropylene segment dominated the market with a 40.4% share in 2024.

- By material, the polyethylene segment is expected to grow at the fastest CAGR of 5.2% during the projected period.

- By application, the film and sheet segment held 42.8% market share in 2024.

- By application, the pipes and profiles segment is expected to grow at the fastest CAGR of 5.3% during the study period.

- By end-use industry, the packaging segment dominated the market with 42.5% share in 2024.

- By end-use industry, the automotive segment is expected to grow at the fastest CAGR of 5.2% over the forecast period.

Types of Plastic Processing Machines

In the plastic industry, there are several types of machines, each designed for a specific purpose. Below, we detail some of the main categories of plastic processing machinery and how they contribute to transforming this material into final products.

1. Extrusion Machines

Extrusion is one of the most common ways to process plastic. Plastic extrusion machines work by pushing molten material through a mold to create a continuous shape, such as tubes, sheets, or profiles. The versatility of this process makes it ideal for a wide range of applications, from pipes to plastic films.

A practical example: Imagine a manufacturer of irrigation systems needing to produce kilometers of polyethylene tubing. Extrusion machines allow these pipes to be produced continuously, with consistency that ensures quality in every meter produced. Furthermore, the flexibility of the process allows for quick mold changes to produce pipes of different diameters according to customer needs.

2. Injection Molding Machines

Injection molding is another cornerstone of plastic processing machinery. This method involves injecting molten plastic into a mold where it cools and solidifies, creating high-precision parts. It is widely used to manufacture plastic products that require specific details, such as electronic components, toys, and automotive parts.

For example, an automotive company can use injection molding to manufacture a vehicle’s control panel. Every button, slot, and curve on the panel must be precisely as specified in the design. Thanks to injection molding machines, it is possible to produce thousands of these panels with uniform quality, ensuring customer satisfaction.

3. Plastic Recycling Machines

Recycling has become a crucial aspect of the plastic industry, and plastic processing machinery plays a vital role in this area. Plastic recycling machines, such as shredders and granulators, allow plastic waste to be transformed into reusable material. This process not only reduces waste but also decreases dependence on virgin raw materials.

Consider a city committed to sustainability that collects plastic waste through recycling programs. This waste is taken to a plant where machines shred, wash, and process it to create new plastic pellets, ready to be reused. Thus, what could have ended up in a landfill becomes new plastic products, promoting a circular economy.

4. Material Handling and Transportation Systems

A key part of plastic transformation is efficiently moving materials within the production plant. This is where material handling and transportation systems, including conveyor belts, hoppers, and loading devices, come in. These systems are designed to move material from one point to another quickly and safely, optimizing workflow and ensuring that each part of the process runs smoothly.

For example, in a factory that processes tons of plastic every day, conveyor belts ensure that material moves quickly from the shredding stage to the washing stage and then to molding, without interruptions or the need for manual intervention. This type of machinery not only saves time but also significantly reduces operational costs.

The Importance of Machinery Maintenance

To ensure that plastic processing machinery operates at maximum performance, proper maintenance is essential. Machinery failures can lead to costly downtime and affect the quality of the final product. This is why companies must have a well-structured preventive maintenance plan.

A company manufacturing plastic parts for the construction sector could face huge losses if an injection molding machine stops working in the middle of a production cycle. However, with good preventive maintenance, potential problems can be identified and corrected before they occur, ensuring continuous, uninterrupted production.

The Role of Plastic in Modern Industry

Plastic is everywhere—from food packaging and car parts to medical devices and electronic components. Its versatility and lightness make it an essential material in the modern world. However, its true potential can only be harnessed through plastic processing machinery, which ensures optimal quality, minimizes waste, and speeds up production times.

Take, for example, a food packaging factory. Every day, thousands of tons of plastic are processed, transforming raw materials into final products that meet rigorous food safety standards. This entire process depends on high-performance machinery that controls the temperature, pressure, and quality of the plastic. Without these machines, maintaining the consistency and quality of the packaging would be an arduous task.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5992

Plastic Processing Machinery Market Report Scope

| Report Attribute | Details |

| Market size value in 2026 | USD 27.50 billion |

| Revenue forecast in 2035 | USD 41.40 billion |

| Growth rate | CAGR of 4.65% from 2026 to 2035 |

| Base year for estimation | 2024 |

| Historical data | 2018 - 2025 |

| Forecast period | 2026 - 2035 |

| Segments covered | By Type, By Operation Mode, By Material, By Application, By End-Use Industry, By Region |

| Regional scope | North America, Europe, Asia Pacific, Latin America, MEA |

| Country scope | U.S.; Canada; Mexico; Germany; France; Italy; U.K.; China; India; Japan; South Korea; Australia; Brazil; Argentina; Saudi Arabia; South Africa |

| Key companies profiled | The Japan Steel Works, Ltd. (JSW); ARBURG GmbH + Co KG; Husky Injection Molding Systems Ltd; Sumitomo Heavy Industries, Ltd.; Persimmon Technologies; Milacron LLC; Haitian International Holdings Limited; Chen Hsong Holdings Limited; ENGEL Austria GmbH; Nissei Plastic Industrial Co., Ltd.; Krauss-Maffei Corporation; Alpha Marathon Film Extrusion Technologies Inc. |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Plastic Machinery as a Key to Success

Plastic transformation largely depends on the plastic processing machinery employed by each company. From extrusion and injection molding to recycling and material handling, each machine plays an essential role in creating high-quality products that are integral to our daily lives.

Investing in high-quality plastic processing machinery not only improves efficiency and productivity but also contributes to a more sustainable approach to plastic production. With automation, proper maintenance, and constant innovation, the plastic industry can continue to evolve to meet the demands of an increasingly demanding market.

If you’re looking to improve your production process or upgrade your machinery, contact us today for personalized advice and to find the perfect solution for your needs. We’re here to help you take your plastic production to the next level, ensuring positive and sustainable results.

Key Private Industry Investments in the Plastic Processing Machinery Industry:

- Main Street Capital's investment in Pinnacle Plastic Products: This was one of the largest private equity deals in the US packaging industry in Q4 2023.

- Comar LLC's acquisition of Automatic Plastics Ltd.: This 2022 acquisition strengthened Comar's expertise in pharmaceutical and medical device packaging.

- Hillenbrand's acquisition of Herbold Meckesheim GmbH: This 2022 deal enhanced Hillenbrand's position in the recycling industry and commitment to sustainability.

- Haitian International's new production facility in Serbia: This expansion in 2023 aims to increase production and logistics for European operations.

-

DuPont's acquisition of Spectrum Plastics Group: In 2021, this acquisition gave DuPont a strong foothold in the growing market for medical plastic products.

What Are the Major Trends in the Plastic Processing Machinery Market?

- Growing focus on sustainability, with increasing adoption of machinery for recycling and processing biodegradable or recyclable plastics.

- Rising integration of automation and smart manufacturing, including robotics and energy-efficient systems, is expected to boost productivity and precision.

- Shift toward lightweight and high-performance materials, driven by demand in automotive and packaging sectors.

- Expansion in emerging markets, especially in the Asia Pacific, is being fuelled by industrialisation and favourable manufacturing policies.

- Innovation in energy-efficient processing technologies, as companies develop machines that consume less power and reduce waste.

How Does AI Influence the Growth of the Plastic Processing Machinery Industry in 2025?

In 2025, AI is accelerating the growth of the plastic processing machinery industry by enabling smarter, more efficient operations. It powers predictive maintenance systems that catch machine issues before breakdowns, integrates with robotics and digital-twin frameworks to automate and refine moulding and extrusion, and uses real-time sensor data to optimise process parameters for reduced waste. AI-driven quality control systems help detect defects more reliably than manual inspection, improving consistency, while machine learning based analytics guide resource and energy consumption. Contributing to more sustainable production.

Market Opportunity

Could Smarter Maintenance Cut Machine Downtime?

AI-driven maintenance offers the plastics processing industry a major opportunity by forecasting equipment failures and enabling proactive servicing, which improves uptime and lowers costs.

Can AI Make Recycling Cleaner and More Scalable?

By powering vision-based sorting systems and robotics, AI enhances the identification and separation of plastic types, boosting recycling efficiency and purity while cutting waste.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5992

Plastic Processing Machinery Market Segmentation Insights

Type Insights:

Why the Injection Moulding Machines Segment Dominated the Plastic Processing Machinery Market?

The injection moulding machines segment dominated the market, supported by its wide application across packaging, automotive, consumer goods, and medical product manufacturing. This segment continues to attract strong demand because of its ability to deliver high production efficiency, consistent product quality, and flexibility in handling complex designs. Manufacturers prefer injection moulding machinery for its precision and adaptability, which makes it suitable for mass production environments where speed and reliability are essential.

The blow moulding machines segment is projected to grow at the fastest pace in the market as industries increasingly require lightweight and durable hollow plastic products. Rising usage in packaging, especially for bottles and containers, is strengthening demand for blow moulding technology. Continuous advancements in machine automation and energy efficiency are further encouraging adoption across manufacturing facilities looking to improve productivity and sustainability.

Operation Mode Insights:

Which Operation Mode Segment Held the Dominated the plastic processing machinery market in 2024?

The hydraulic segment maintained a dominated the market due to its strong performance in high-pressure applications and sturdy operational capability. These machines are preferred in heavy-duty manufacturing environments where reliability and power efficiency are necessary for consistent production. Their long-standing presence in industrial setups continues to support their widespread usage across diverse sectors.

The electric segment is expected to grow rapidly in the market as manufacturers move toward quieter and more energy-efficient solutions. Electric machines support precise control, reduced operational costs, and improved repeatability, making them suitable for advanced manufacturing processes and smart factory environments focused on automation and sustainability.

Material Insights:

How did the Polypropylene Segment hold the Largest Share of the Plastic Processing Machinery Market in 2024?

The polypropylene segment held largest share of the market in 2024, due to its wide usage in packaging, automotive, components, and consumer products. Its durability, lightweight nature, and cost efficiency make it a preferred choice for high-volume production. The consistent demand for polypropylene-based products continues to support steady machinery deployment tailored for its processing.

The polyethene segment is anticipated to expand at a rapid pace in the market as its flexibility and recyclability gain greater industry preference. Growing demand in packaging and industrial applications is driving manufacturers to invest in advanced equipment that supports efficient polyethene processing while aligning with sustainability goals.

Application Insights:

Which Application Segment Dominates the Plastic Processing Machinery Market?

The film and sheet segment dominated the market due to growing usage in food packaging, agricultural covers, and industrial wrapping solutions. The rising need for flexible and proactive packaging materials continues to strengthen the role of film and sheet machinery in high-demand production environments focused on efficiency and product safety.

The pipes and profiles segment is projected to witness fastest expansion in the market as infrastructure development and construction activities increase. Demand for durable plastic piping systems in water management, drainage, and industrial projects is encouraging manufacturers to adopt advanced machinery that produces diverse, consistent output and enhanced structural performance.

End-Use Industry Insights:

What Made the packaging Segment Dominate the Industrial Water Treatment Chemicals Market?

The packaging segment maintained a dominant position in the market, driven by rising consumption of packaged goods and the need for proactive, lightweight materials. The continuous evolution of flexible packaging solutions and sustainable packaging trends further boosts machinery demand across food, beverage, and consumer product sectors.

The automotive segment is anticipated to grow at a rapid rate in the market as manufacturers increasingly adopt lightweight plastic components to improve vehicle efficiency. The push for advanced interior and exterior automotive parts made from durable plastics is strengthening the demand for specialised processing machinery across production facilities.

➤ Contact Us: sales@towardschemandmaterials.com | ☎ +1 804 441 9344

Regional Insights

Why Is Asia Pacific Dominating the Plastic Processing Machinery Market?

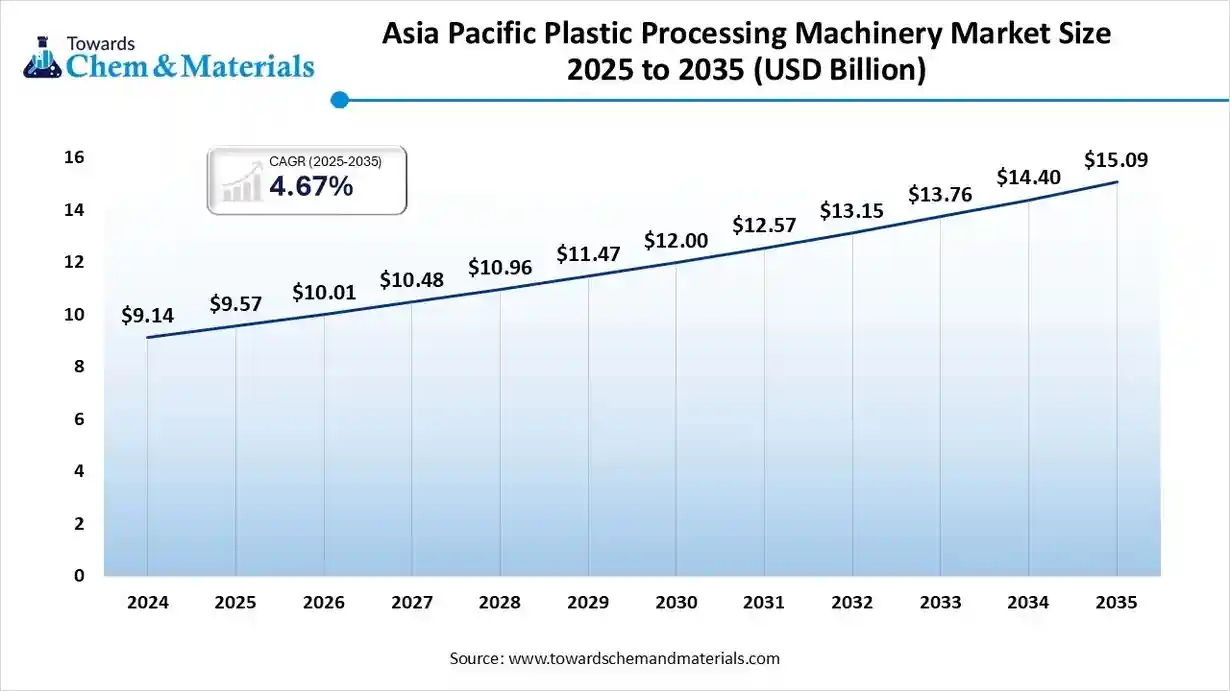

The Asia Pacific plastic processing machinery market size was valued at USD 9.57 billion in 2025 and is expected to reach USD 15.09 billion by 2035, growing at a CAGR of 4.67% from 2025 to 2035.Asia Pacific dominated the market with a 36.4% share in 2024

The Asia Pacific region dominates the global market thanks to rapid industrialisation, high demand for consumer goods, and a robust manufacturing ecosystem in countries such as China and India. The region’s growth is fuelled by favourable government policies, expanding urbanisation, and a rising middle class that is increasing consumption of plastics across sectors like packaging, automotive, and construction.

The growing demand for lightweight materials in sectors such as automotive, electronics, and packaging is expected to speed up the market growth across China. As manufacturers focus on reducing weight for improved fuel efficiency and product performance, the need for advanced machinery to process lightweight plastic components rises. Furthermore, domestic and international market expansion in China, supported by its strong manufacturing sector and global trade reach, boosts demand for plastic processing machinery. Continued technological advancements and export-driven production further contribute to the growth of the market.

China Plastic Processing Machinery Market Trends

China plays a crucial role in driving the Asia Pacific’s dominance, as its strong export-oriented economy and heavy manufacturing capacity push up demand for advanced plastic processing machinery. The country’s growing need for lightweight, high-performance plastics in sectors such as packaging and automotive further amplifies investment in energy-efficient and sustainable equipment.

Why Is North America the Growing Region?

North America is emerging rapidly in the market due to a strong shift toward a circular economy and increasing demand for machinery capable of processing recycled and biodegradable plastics. Sustainability goals, coupled with consumer and regulatory pressure, are driving investments in advanced, energy-efficient plastic processing systems. Digitalisation and Industry 4.0 technologies are also gaining momentum, with manufacturers embracing smart machines that offer real-time monitoring and predictive maintenance. The expansion of high-precision applications in healthcare and automotive further fuels this growth trajectory.

U.S. Plastic Processing Machinery Market Trends

The U.S. plays a central role in the North American market, powered by its mature manufacturing base and high adoption of automation, robotics, and IA-enabled control systems in plastic processing. Strict environmental regulations and sustainability targets encourage the use of electric and hybrid machinery that can handle sustainable resins. A strong research and development ecosystem, access to capital, and a skilled workforce further support demand for cutting-edge processing equipment.

Europe Plastic Processing Machinery Market Trends

Europe plastic processing machinery market is expected to record the highest CAGR of 4.2% from 2025 to 2030, due to the emphasis on eco-friendly plastic materials and recycling technologies, coupled with expansion in the medical and packaging sectors. As sustainability becomes a priority, there is a rising demand for machinery capable of producing recyclable, biodegradable plastics. Also, the medical and packaging industries require advanced, precise machinery for producing high-quality plastic components and packaging solutions. These trends, supported by stringent environmental regulations and the need for innovation in recycling technologies, are fueling demand for cutting-edge plastic processing equipment across Europe.

Government initiatives in Germany to promote green and sustainable manufacturing processes are expected to drive the plastic processing machinery industry. With regulations favoring eco-friendly production, there is an increasing demand for machinery capable of processing recyclable and biodegradable plastics. In addition, the strong focus of Germany on high-precision and customized machinery, especially in the automotive and medical industries, is boosting market growth. These trends push manufacturers to invest in advanced technologies that improve efficiency, reduce waste, and meet stringent environmental standards, further surging the demand for specialized plastic processing solutions.

France is anticipated to record notable growth over the forecast period with the growing interest in bioplastics and the rising inclination toward customized plastic products. As environmental concerns increase, there is a surge in demand for bioplastics, which require specialized processing technologies. Besides, industries are increasingly seeking customized plastic products, pushing the need for advanced machinery capable of delivering high precision and flexibility in production. These trends are driving innovation in plastic processing equipment as manufacturers invest in new technologies to meet the evolving demand for sustainable, tailored, and high-performance plastic solutions in France.

Top Companies in the Plastic Processing Machinery Market & Their Offerings

- Arburg GmbH + Co KG Manufactures a wide range of injection molding machines (ALLROUNDERs) and additive manufacturing solutions.

- Husky Injection Molding Systems Ltd. Specializes in injection molding systems for high-productivity packaging applications, especially PET preforms.

- Sumitomo Heavy Industries Ltd. Offers precise, high-cycle all-electric injection molding machines with advanced integrated applications.

- Milacron Holdings Corp. Provides injection molding and extrusion machines, highly engineered systems, and mold components globally.

- Toshiba Machine Co., Ltd. (Shibaura Machine) Supplies high-precision injection molding, die-casting, and extrusion machinery.

- JSW Plastics Machinery Inc. Manufactures reliable all-electric injection and extrusion machines for precise production.

- Nissei Plastic Industrial Co., Ltd. Offers diverse hybrid and all-electric injection molding machines known for precision and innovation.

- Wittmann Battenfeld GmbH Develops integrated injection molding machines, robots, and auxiliary equipment for automated production cells.

- Battenfeld-Cincinnati Group Specializes in manufacturing high-performance extrusion lines for pipes, profiles, sheets, and pellets.

- Negri Bossi S.p.A. Offers a comprehensive range of electric, hybrid, and hydraulic injection molding machines for various industry applications.

More Insights in Towards Chemical and Materials:

Plastics Market Size to Worth USD 984.11 Billion by 2034

U.S. Plastics Market Size to Surge USD 131.34 Billion by 2034

Plastic Lidding Films Market Size to Hit USD 5.13 Billion by 2034

U.S. Recycled Plastics Market Size to Reach USD 131.33 Bn by 2034

Recycled Plastics Market Size to Surpass USD 190.25 Billion by 2035

Asia Pacific Plastic Compounding Market Size to Surpass USD 77.60 Bn by 2034

Plastic Injection Molding Market Size to Worth USD 17.65 Bn by 2034

Corrugated Plastic Sheets Market Size to Reach USD 3.05 Bn by 2034

Plastic Compounding Market Size to Reach USD 148.83 Bn by 2034

Biodegradable Plastics Market Size to Reach USD 91.26 Billion by 2034

Microplastic Recycling Market Size to Hit USD 817 Million by 2034

U.S. Recycled Plastics in Green Building Materials Market Size and Top Companies Analysis, 2034

Europe Recycled Plastics Market Size to Surpass USD 33.84 Bn by 2035

Asia Pacific Recycled Plastics Market Size to Surpass USD 72.11 Bn by 2034

Recycled Engineering Plastics Market Size to Hit USD 7.89 Billion by 2034

Plastic Waste Management Market Size to Reach USD 54.66 Bn by 2034

Mechanical Recycling of Plastics Market Size to Surge USD 92.86 Bn by 2034

Recycled Plastic Pipes Market Size to Hit USD 20.08 Billion by 2034

Carbon Fiber Reinforced Plastic (CFRP) Market Size to Surge USD 48.08 Bn by 2034

Plastic Hot and Cold Pipe Market Size to Hit USD 14.93 Bn by 2034

Commodity Plastics Market Size to Hit USD 666.76 Billion by 2034

U.S. Biodegradable Plastics Market Size to Hit USD 5.27 Billion by 2034

U.S. Smart Plastics In Precision Agriculture Market Size to Reach USD 1,396.39 Mn by 2034

U.S. Plastic Lidding Films Market Size to Surge USD 1,078.32 Mn by 2034

Plastic Processing Machinery Market Top Key Companies:

- The Japan Steel Works, Ltd. (JSW)

- ARBURG GmbH + Co KG

- Husky Injection Molding Systems Ltd

- Sumitomo Heavy Industries, Ltd.

- Persimmon Technologies

- Milacron LLC

- Haitian International Holdings Limited

- Chen Hsong Holdings Limited

- ENGEL Austria GmbH

- Nissei Plastic Industrial Co., Ltd.

- Krauss-Maffei Corporation

- Alpha Marathon Film Extrusion Technologies Inc.

Recent Developments

- In May 2025, Haitian Group and Haier Smart Home Co. signed a global strategic cooperation agreement to deepen collaboration on intelligent manufacturing, AI, big data, and customized production. The signing ceremony for this strategic cooperation agreement was held at the Haier Ecosystem Brand Center.

- In October 2024, Milacron unveiled the eQ180, an advanced all-electric injection molding machine featuring monosandwich technology. This innovative machine enables efficient production of multi-layer parts using post-consumer recyclable (PCR) materials for enhanced sustainability and performance.

- In June 2024, JianTai launched its advanced Recycled Plastic Extrusion Machine, designed to improve the efficiency and effectiveness of plastic recycling, catering to the evolving needs of the industry for enhanced sustainability.

Plastic Processing Machinery Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2034. For this study, Towards Chemical and Materials has segmented the global Plastic Processing Machinery Market

By Type

- Injection Molding Machines

- Blow Molding Machines

- Extrusion Machines

- Thermoforming Machines

- Compression Molding Machines

By Operation Mode

- Hydraulic

- Electric

- Hybrid

By Material

- Polypropylene

- Polyethylene

- PVC

- ABS

- Polystyrene

By Application

- Film and Sheet

- Pipes and Profiles

- Wires and Cables

- Bottles and Containers

By End-Use Industry

- Packaging

- Automotive

- Construction

- Consumer Goods

- Electronics

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5992

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.